Quality Control

Quality Control

Catch quality issues when they cost $100 to fix, not $20,000 after they're buried.

Catch quality issues caught when they cost $100, not $20,000 to remedy. Complete inspection documentation for every critical stage. Defects prevented, not discovered after they're expensive to fix.

The Problem: Quality Issues Discovered Too Late Cost Exponentially More

Construction has critical hold points—stages where work must stop for inspection before proceeding. Concrete must be inspected before pouring. Waterproofing must be verified before tiling. Framing must be checked before closing walls. These checks exist because fixing issues after the next stage begins costs dramatically more than catching them beforehand.

In manual operations, hold points get missed. Someone forgot to schedule the inspection. The crew proceeded because they were on schedule. The ITP was completed hastily or incompletely because no one was checking quality. Work continues, the issue gets buried, and weeks later it's discovered—requiring demolition, rework, and delays that cost 10-100x more than proper inspection would have.

Even when ITPs are completed, they're often inadequate—checkboxes ticked without photos, measurements missing, sign-offs unclear. When issues arise later, you can't prove whether inspections were done properly or if problems existed before work continued.

The real cost isn't just the rework—it's the project delays, the client dissatisfaction, the reputation damage, and the disputes with subcontractors about whether proper process was followed.

The Solution: Digital Quality Enforcement That Prevents Work Proceeding Without Inspection

Quality Control makes hold points impossible to bypass and ensures ITPs are completed properly—with AI verification catching issues before they escalate.

Enforced Hold Points Critical stages are marked as hold points in the system. Work literally cannot proceed—can't mark as complete, can't move to next task, can't sign off—until required inspections are completed and approved. No forgetting, no "we'll do it later," no proceeding without checks.

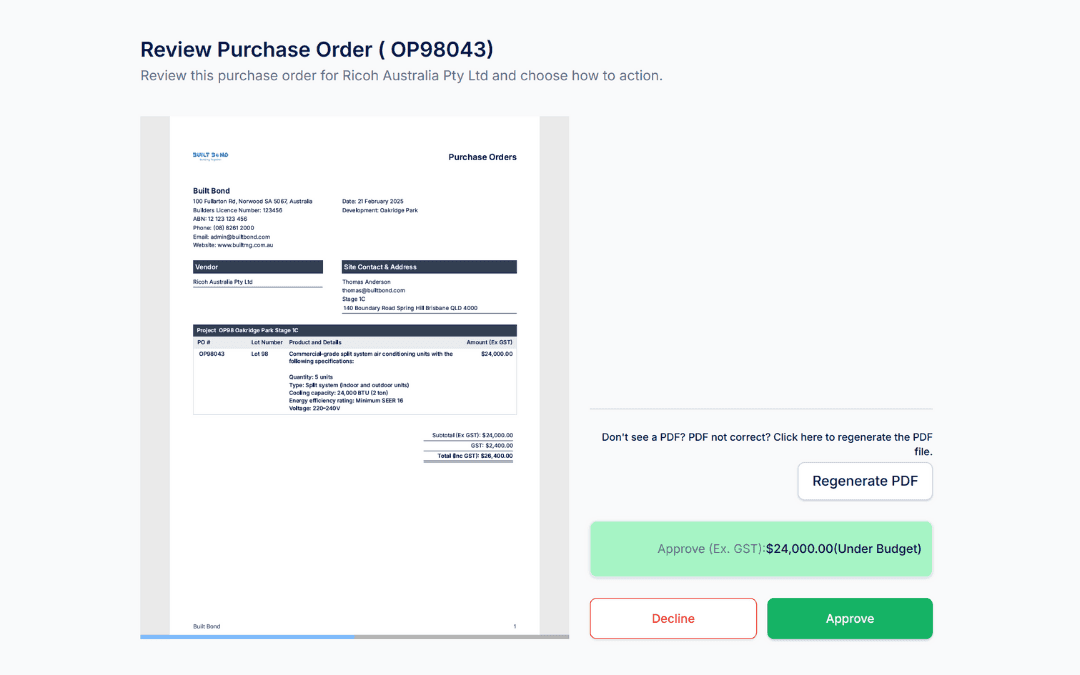

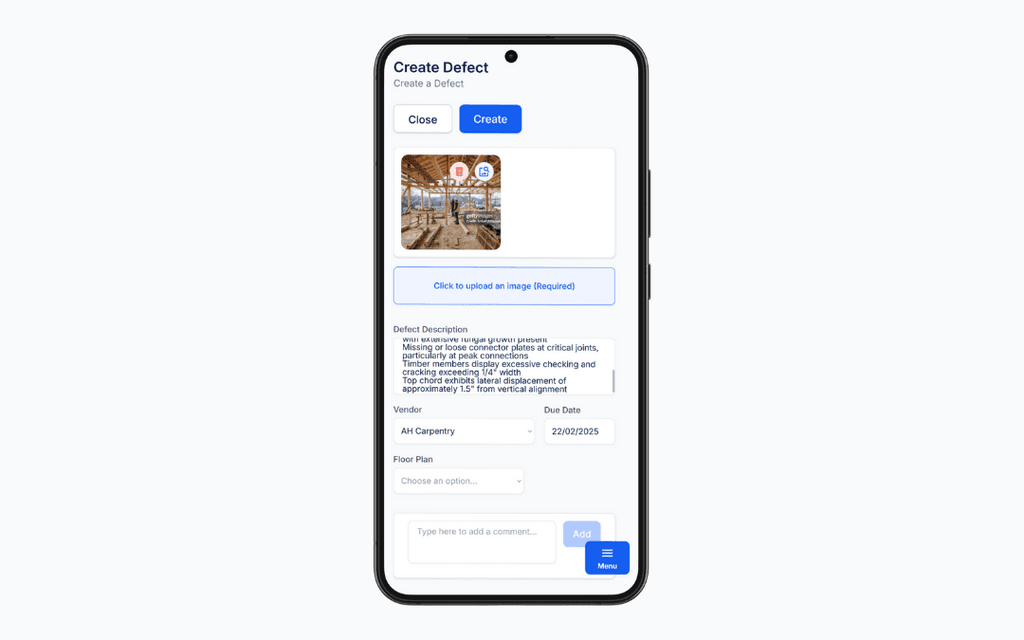

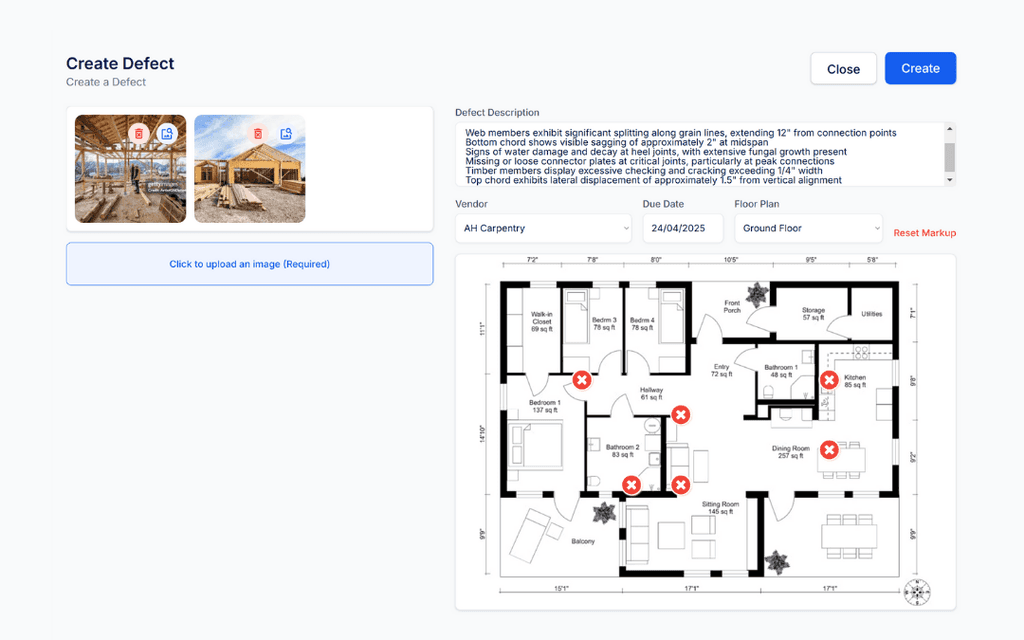

Digital Inspection Test Plans (ITPs) Workers complete ITPs digitally at hold points—guided checklists with required photos, measurements, observations, and verifications. Can't skip questions. Can't mark complete without documentation. Every critical check captured systematically.

AI ITP Review & Validation AI reviews completed ITPs checking for: Are all required photos included? Are measurements within tolerance? Are observations detailed enough? Are there obvious issues visible in photos? Flags incomplete or problematic ITPs before construction manager reviews.

Photo-Documented Quality Evidence Every inspection requires photo documentation—overview shots, close-ups of critical areas, measurements visible in frame. Creates indisputable record of condition at hold point. No "he said/she said" disputes about whether issues existed when inspection occurred.

Automatic Escalation of Issues When AI flags problems in ITPs—missing documentation, measurements out of spec, photos showing potential defects—it escalates to construction managers immediately. Issues get addressed before work proceeds, not discovered after they're buried.

Issue Tracking to Resolution Problems identified during quality checks feed directly into defect tracking. Assigned to responsible trades, tracked to resolution, verified complete before work proceeds. Quality issues don't get forgotten or ignored—they block progress until resolved.

Staged Quality Gates Different hold points have different requirements—foundation inspections need structural verification, waterproofing needs membrane testing, electrical needs compliance certification. ITPs are customized for each stage, ensuring appropriate checks happen at the right times.

Complete Quality Audit Trail Every hold point inspection, every ITP completion, every photo, every measurement, every sign-off—automatically documented with timestamps and responsible parties. Prove quality process was followed when clients, surveyors, or regulators ask.

Benefits & Outcomes

Catch Issues at $100, Not $20,000 A waterproofing defect caught before tiling costs $100 in membrane repair. Same issue discovered after tiles are installed costs $20,000 in demolition, re-waterproofing, and re-tiling. Quality Control catches problems when they're cheap to fix.

Zero Hold Points Bypassed Work cannot proceed without completed inspections. Concrete can't be poured without formwork inspection. Walls can't close without framing verification. The system enforces what manual process hopes people remember.

AI Catches Incomplete Inspections ITPs marked "complete" but missing required photos? Measurements not recorded? Observations too vague? AI flags these before construction manager review, ensuring inspections are actually thorough, not just checked off.

Eliminate Disputes About Quality Process Complete photo documentation at every hold point proves what condition existed when work proceeded. No arguments about whether defects existed before or after inspections. The record is indisputable.

Prevent Costly Rework Issues caught during inspections cost hours to fix. Same issues discovered after work proceeds cost days or weeks. Proper quality enforcement dramatically reduces expensive rework from preventable defects.

Protect Client Relationships Quality issues discovered during construction are manageable. Issues discovered after handover damage client trust and create warranty nightmares. Systematic quality control prevents problems from reaching clients.

Subcontractor Accountability When trades complete work improperly, photo-documented inspections prove the issue existed at specific stages. Clear accountability for who's responsible and when problems occurred—reducing disputes and ensuring proper remediation.

The Problem: Quality Issues Discovered Too Late Cost Exponentially More

Construction has critical hold points—stages where work must stop for inspection before proceeding. Concrete must be inspected before pouring. Waterproofing must be verified before tiling. Framing must be checked before closing walls. These checks exist because fixing issues after the next stage begins costs dramatically more than catching them beforehand.

In manual operations, hold points get missed. Someone forgot to schedule the inspection. The crew proceeded because they were on schedule. The ITP was completed hastily or incompletely because no one was checking quality. Work continues, the issue gets buried, and weeks later it's discovered—requiring demolition, rework, and delays that cost 10-100x more than proper inspection would have.

Even when ITPs are completed, they're often inadequate—checkboxes ticked without photos, measurements missing, sign-offs unclear. When issues arise later, you can't prove whether inspections were done properly or if problems existed before work continued.

The real cost isn't just the rework—it's the project delays, the client dissatisfaction, the reputation damage, and the disputes with subcontractors about whether proper process was followed.

The Solution: Digital Quality Enforcement That Prevents Work Proceeding Without Inspection

Quality Control makes hold points impossible to bypass and ensures ITPs are completed properly—with AI verification catching issues before they escalate.

Enforced Hold Points Critical stages are marked as hold points in the system. Work literally cannot proceed—can't mark as complete, can't move to next task, can't sign off—until required inspections are completed and approved. No forgetting, no "we'll do it later," no proceeding without checks.

Digital Inspection Test Plans (ITPs) Workers complete ITPs digitally at hold points—guided checklists with required photos, measurements, observations, and verifications. Can't skip questions. Can't mark complete without documentation. Every critical check captured systematically.

AI ITP Review & Validation AI reviews completed ITPs checking for: Are all required photos included? Are measurements within tolerance? Are observations detailed enough? Are there obvious issues visible in photos? Flags incomplete or problematic ITPs before construction manager reviews.

Photo-Documented Quality Evidence Every inspection requires photo documentation—overview shots, close-ups of critical areas, measurements visible in frame. Creates indisputable record of condition at hold point. No "he said/she said" disputes about whether issues existed when inspection occurred.

Automatic Escalation of Issues When AI flags problems in ITPs—missing documentation, measurements out of spec, photos showing potential defects—it escalates to construction managers immediately. Issues get addressed before work proceeds, not discovered after they're buried.

Issue Tracking to Resolution Problems identified during quality checks feed directly into defect tracking. Assigned to responsible trades, tracked to resolution, verified complete before work proceeds. Quality issues don't get forgotten or ignored—they block progress until resolved.

Staged Quality Gates Different hold points have different requirements—foundation inspections need structural verification, waterproofing needs membrane testing, electrical needs compliance certification. ITPs are customized for each stage, ensuring appropriate checks happen at the right times.

Complete Quality Audit Trail Every hold point inspection, every ITP completion, every photo, every measurement, every sign-off—automatically documented with timestamps and responsible parties. Prove quality process was followed when clients, surveyors, or regulators ask.

Benefits & Outcomes

Catch Issues at $100, Not $20,000 A waterproofing defect caught before tiling costs $100 in membrane repair. Same issue discovered after tiles are installed costs $20,000 in demolition, re-waterproofing, and re-tiling. Quality Control catches problems when they're cheap to fix.

Zero Hold Points Bypassed Work cannot proceed without completed inspections. Concrete can't be poured without formwork inspection. Walls can't close without framing verification. The system enforces what manual process hopes people remember.

AI Catches Incomplete Inspections ITPs marked "complete" but missing required photos? Measurements not recorded? Observations too vague? AI flags these before construction manager review, ensuring inspections are actually thorough, not just checked off.

Eliminate Disputes About Quality Process Complete photo documentation at every hold point proves what condition existed when work proceeded. No arguments about whether defects existed before or after inspections. The record is indisputable.

Prevent Costly Rework Issues caught during inspections cost hours to fix. Same issues discovered after work proceeds cost days or weeks. Proper quality enforcement dramatically reduces expensive rework from preventable defects.

Protect Client Relationships Quality issues discovered during construction are manageable. Issues discovered after handover damage client trust and create warranty nightmares. Systematic quality control prevents problems from reaching clients.

Subcontractor Accountability When trades complete work improperly, photo-documented inspections prove the issue existed at specific stages. Clear accountability for who's responsible and when problems occurred—reducing disputes and ensuring proper remediation.

The Problem: Quality Issues Discovered Too Late Cost Exponentially More

Construction has critical hold points—stages where work must stop for inspection before proceeding. Concrete must be inspected before pouring. Waterproofing must be verified before tiling. Framing must be checked before closing walls. These checks exist because fixing issues after the next stage begins costs dramatically more than catching them beforehand.

In manual operations, hold points get missed. Someone forgot to schedule the inspection. The crew proceeded because they were on schedule. The ITP was completed hastily or incompletely because no one was checking quality. Work continues, the issue gets buried, and weeks later it's discovered—requiring demolition, rework, and delays that cost 10-100x more than proper inspection would have.

Even when ITPs are completed, they're often inadequate—checkboxes ticked without photos, measurements missing, sign-offs unclear. When issues arise later, you can't prove whether inspections were done properly or if problems existed before work continued.

The real cost isn't just the rework—it's the project delays, the client dissatisfaction, the reputation damage, and the disputes with subcontractors about whether proper process was followed.

The Solution: Digital Quality Enforcement That Prevents Work Proceeding Without Inspection

Quality Control makes hold points impossible to bypass and ensures ITPs are completed properly—with AI verification catching issues before they escalate.

Enforced Hold Points Critical stages are marked as hold points in the system. Work literally cannot proceed—can't mark as complete, can't move to next task, can't sign off—until required inspections are completed and approved. No forgetting, no "we'll do it later," no proceeding without checks.

Digital Inspection Test Plans (ITPs) Workers complete ITPs digitally at hold points—guided checklists with required photos, measurements, observations, and verifications. Can't skip questions. Can't mark complete without documentation. Every critical check captured systematically.

AI ITP Review & Validation AI reviews completed ITPs checking for: Are all required photos included? Are measurements within tolerance? Are observations detailed enough? Are there obvious issues visible in photos? Flags incomplete or problematic ITPs before construction manager reviews.

Photo-Documented Quality Evidence Every inspection requires photo documentation—overview shots, close-ups of critical areas, measurements visible in frame. Creates indisputable record of condition at hold point. No "he said/she said" disputes about whether issues existed when inspection occurred.

Automatic Escalation of Issues When AI flags problems in ITPs—missing documentation, measurements out of spec, photos showing potential defects—it escalates to construction managers immediately. Issues get addressed before work proceeds, not discovered after they're buried.

Issue Tracking to Resolution Problems identified during quality checks feed directly into defect tracking. Assigned to responsible trades, tracked to resolution, verified complete before work proceeds. Quality issues don't get forgotten or ignored—they block progress until resolved.

Staged Quality Gates Different hold points have different requirements—foundation inspections need structural verification, waterproofing needs membrane testing, electrical needs compliance certification. ITPs are customized for each stage, ensuring appropriate checks happen at the right times.

Complete Quality Audit Trail Every hold point inspection, every ITP completion, every photo, every measurement, every sign-off—automatically documented with timestamps and responsible parties. Prove quality process was followed when clients, surveyors, or regulators ask.

Benefits & Outcomes

Catch Issues at $100, Not $20,000 A waterproofing defect caught before tiling costs $100 in membrane repair. Same issue discovered after tiles are installed costs $20,000 in demolition, re-waterproofing, and re-tiling. Quality Control catches problems when they're cheap to fix.

Zero Hold Points Bypassed Work cannot proceed without completed inspections. Concrete can't be poured without formwork inspection. Walls can't close without framing verification. The system enforces what manual process hopes people remember.

AI Catches Incomplete Inspections ITPs marked "complete" but missing required photos? Measurements not recorded? Observations too vague? AI flags these before construction manager review, ensuring inspections are actually thorough, not just checked off.

Eliminate Disputes About Quality Process Complete photo documentation at every hold point proves what condition existed when work proceeded. No arguments about whether defects existed before or after inspections. The record is indisputable.

Prevent Costly Rework Issues caught during inspections cost hours to fix. Same issues discovered after work proceeds cost days or weeks. Proper quality enforcement dramatically reduces expensive rework from preventable defects.

Protect Client Relationships Quality issues discovered during construction are manageable. Issues discovered after handover damage client trust and create warranty nightmares. Systematic quality control prevents problems from reaching clients.

Subcontractor Accountability When trades complete work improperly, photo-documented inspections prove the issue existed at specific stages. Clear accountability for who's responsible and when problems occurred—reducing disputes and ensuring proper remediation.

Frequenly asked questions

Frequenly asked questions

Frequenly asked questions

What happens if someone tries to proceed past a hold point without completing the ITP?

They can't. The system blocks marking that stage complete until required inspections are documented and approved. Work literally cannot progress without quality compliance.

How does AI know if an ITP is completed properly?

AI checks for required elements: Are specified photos present? Are measurements recorded? Are observations detailed (not just "looks good")? Are there visible issues in photos that should be flagged? Incomplete or problematic ITPs get escalated before approval.

Can we customize ITPs for different project types or jurisdictions?

Yes—create custom inspection requirements for each hold point based on your standards, project type, and local compliance requirements. The system enforces your specific quality process, not generic checklists.

What if the AI flags something that's actually not a problem?

Construction managers review all flagged items. If AI escalates something incorrectly, manager can approve with notes explaining why. Over time, the system learns your standards and improves accuracy.

Can external inspectors (surveyors, certifiers) access our ITPs?

Yes—share ITP documentation with external parties as needed. Shows professional, thorough quality process and provides them with detailed photo evidence of conditions at each stage.

What happens if someone tries to proceed past a hold point without completing the ITP?

They can't. The system blocks marking that stage complete until required inspections are documented and approved. Work literally cannot progress without quality compliance.

How does AI know if an ITP is completed properly?

AI checks for required elements: Are specified photos present? Are measurements recorded? Are observations detailed (not just "looks good")? Are there visible issues in photos that should be flagged? Incomplete or problematic ITPs get escalated before approval.

Can we customize ITPs for different project types or jurisdictions?

Yes—create custom inspection requirements for each hold point based on your standards, project type, and local compliance requirements. The system enforces your specific quality process, not generic checklists.

What if the AI flags something that's actually not a problem?

Construction managers review all flagged items. If AI escalates something incorrectly, manager can approve with notes explaining why. Over time, the system learns your standards and improves accuracy.

Can external inspectors (surveyors, certifiers) access our ITPs?

Yes—share ITP documentation with external parties as needed. Shows professional, thorough quality process and provides them with detailed photo evidence of conditions at each stage.

What happens if someone tries to proceed past a hold point without completing the ITP?

They can't. The system blocks marking that stage complete until required inspections are documented and approved. Work literally cannot progress without quality compliance.

How does AI know if an ITP is completed properly?

AI checks for required elements: Are specified photos present? Are measurements recorded? Are observations detailed (not just "looks good")? Are there visible issues in photos that should be flagged? Incomplete or problematic ITPs get escalated before approval.

Can we customize ITPs for different project types or jurisdictions?

Yes—create custom inspection requirements for each hold point based on your standards, project type, and local compliance requirements. The system enforces your specific quality process, not generic checklists.

What if the AI flags something that's actually not a problem?

Construction managers review all flagged items. If AI escalates something incorrectly, manager can approve with notes explaining why. Over time, the system learns your standards and improves accuracy.

Can external inspectors (surveyors, certifiers) access our ITPs?

Yes—share ITP documentation with external parties as needed. Shows professional, thorough quality process and provides them with detailed photo evidence of conditions at each stage.

The difference between a $100 fix and a $20,000 disaster is catching quality issues before the next construction stage buries them. Hold points exist for exactly this reason—but they only work if they're actually enforced with proper inspection documentation.

Quality Control makes hold points impossible to bypass, ensures ITPs are completed thoroughly (not just checked off), and uses AI to catch issues before construction managers even review them. Problems get addressed when they're cheap to fix, not after they've become expensive catastrophes.

That's how you deliver quality work while protecting margins from preventable rework costs.

The difference between a $100 fix and a $20,000 disaster is catching quality issues before the next construction stage buries them. Hold points exist for exactly this reason—but they only work if they're actually enforced with proper inspection documentation.

Quality Control makes hold points impossible to bypass, ensures ITPs are completed thoroughly (not just checked off), and uses AI to catch issues before construction managers even review them. Problems get addressed when they're cheap to fix, not after they've become expensive catastrophes.

That's how you deliver quality work while protecting margins from preventable rework costs.

The difference between a $100 fix and a $20,000 disaster is catching quality issues before the next construction stage buries them. Hold points exist for exactly this reason—but they only work if they're actually enforced with proper inspection documentation.

Quality Control makes hold points impossible to bypass, ensures ITPs are completed thoroughly (not just checked off), and uses AI to catch issues before construction managers even review them. Problems get addressed when they're cheap to fix, not after they've become expensive catastrophes.

That's how you deliver quality work while protecting margins from preventable rework costs.

Other Services

Other Services

Other Services

Sometimes the hardest part is reaching out — but once you do, we’ll make the rest easy.

Sometimes the hardest part is reaching out — but once you do, we’ll make the rest easy.

Sometimes the hardest part is reaching out — but once you do, we’ll make the rest easy.